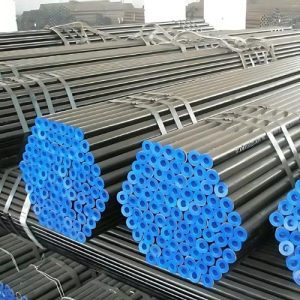

Carbon Steel Seamless Pipe

Carbon Steel Pipe & Tube Solutions by Vikalp Steel Industries

Introduction to Vikalp Steel Industries

Vikalp Steel Industries is a trusted name in the industry, recognized for its extensive stock and supply of premium-quality pipes and tubes. As a leading supplier and stockist, we specialize in providing a comprehensive range of carbon steel pipes and tubes, catering to diverse industry needs. Our commitment to quality, precision, and customer satisfaction makes us a preferred partner for clients worldwide.

Carbon Steel Pipe & Tube Overview

Carbon steel pipes and tubes are widely used for their strength, durability, and cost-effectiveness. These pipes are ideal for conveying fluids, gases, and structural applications across various industries. Vikalp Steel Industries offers carbon steel pipes and tubes in various grades, sizes, and finishes to meet industry standards and customer requirements.

Our Product Range :

Our extensive product range includes:

- Seamless Carbon Steel Pipes

- Welded Carbon Steel Pipes

- Thick-Walled Carbon Steel Pipes

Product Specifications :

| Category | Details |

|---|---|

| Sizes | Pipes: 1/8” NB to 24” NBTubes: 4mm OD to 219mm OD |

| Thickness Options | SCH 5, SCH 10, SCH 20, SCH 40, SCH 80, SCH 160, SCH XXS |

| Material Grades | ASTM A106 Gr. B, ASTM A333, ASTM A53ASTM A335 P1, P5, P9, P11, P22, P91Inconel, Monel, Hastelloy, 254 SMO, 904LUNS S31803, S32205, S32750, S32760Gr 2, Gr 5 TitaniumCuNi 70/30, CuNi 90/10 |

| Connection Types | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Standards | ASTM / ASME: A312, A213, A269, A335, A106, A53, A333DIN / EN / ISO: DIN 17175, EN 10216-5, ISO 1127JIS Standard: JIS G3459, JIS G3463 |

| Tolerance Specifications | Dimensional AccuracyWall Thickness PrecisionLength Tolerance for Custom RequirementsEnd Finish Control for Seamless Assembly |

Chart summarizing the popular standards for carbon steel seamless pipes and tubes:

| Standard | Description | Application |

| ASTM A106 | Seamless carbon steel pipe for high-temperature service | Oil & gas, refineries, power plants |

| ASTM A53 | Black and hot-dipped, zinc-coated, welded and seamless pipes | Water, gas, steam, and structural use |

| ASTM A333 | Seamless and welded steel pipes for low-temperature service | Cryogenic applications, LNG transport |

| ASTM A179 | Seamless cold-drawn low-carbon steel tubes | Heat exchangers, condensers, and boilers |

| ASTM A192 | Seamless carbon steel boiler tubes for high-pressure service | Boiler and superheater tubes |

| ASTM A210 | Seamless medium-carbon steel boiler and superheater tubes | High-pressure boiler applications |

| ASTM A519 | Seamless carbon and alloy steel mechanical tubing | General mechanical and structural uses |

| API 5L | Seamless and welded line pipes (Grades X42-X80) | Oil, gas, and pipeline transportation |

| API 5CT | Seamless casing and tubing for oil and gas wells | Oil well drilling |

| ASME SA106 | Equivalent to ASTM A106 | High-temperature industrial piping |

| ASME SA179 | Equivalent to ASTM A179 | Heat exchangers, condensers, and boilers |

| ASME SA210 | Equivalent to ASTM A210 | Boiler tubes and high-pressure applications |

| DIN 17175 | Seamless tubes for high-temperature applications | Boiler, superheater, and heat exchanger tubes |

| EN 10216-1 | Seamless steel tubes for pressure purposes (non-alloy steel) | Pressure vessel and piping systems |

| EN 10216-2 | Seamless steel tubes for high-temperature applications | Boilers and high-temperature piping |

| EN 10297-1 | Seamless circular steel tubes for mechanical & engineering purposes | Structural and mechanical applications |

| JIS G3454 | Carbon steel pipes for pressure service | Piping systems under moderate pressure |

| JIS G3455 | Carbon steel pipes for high-pressure service | High-pressure fluid transmission |

| JIS G3456 | Carbon steel pipes for high-temperature service | Heat-resistant industrial piping |

Carbon Steel Seamless Pipe & Tube Standards Chart :

| Standard | Material Grades | Chemical Composition (Max %) | Tensile Strength (MPa) | Yield Strength (MPa) | Applications |

| ASTM A106 | A, B, C | C: 0.25-0.35, Mn: 0.27-1.20 | 415-485 | 240-275 | High-temperature service, oil & gas |

| ASTM A53 | A, B | C: 0.30-0.25, Mn: 0.95-1.20 | 330-415 | 205-240 | Water, gas, steam, structures |

| ASTM A333 | Gr. 1, 6 | C: 0.10-0.30, Mn: 0.40-1.06 | 380-415 | 205-240 | Low-temperature service, LNG transport |

| ASTM A179 | Low Carbon Steel | C: 0.06-0.18, Mn: 0.27-0.63 | 325-485 | 180 min | Heat exchangers, condensers, boilers |

| ASTM A192 | Medium Carbon Steel | C: 0.06-0.18, Mn: 0.27-0.63 | 325-485 | 180 min | Boiler tubes, high-pressure service |

| ASTM A210 | A-1, C | C: 0.27-0.35, Mn: 0.93-1.20 | 415-485 | 255-275 | High-pressure boiler tubes |

| ASTM A519 | 1020, 1026 | C: 0.18-0.30, Mn: 0.30-1.00 | 415-485 | 205-275 | Mechanical and structural tubing |

| API 5L | Gr. B, X42-X80 | C: 0.28 max, Mn: 1.40 max | 414-760 | 241-570 | Oil & gas transmission pipelines |

| API 5CT | J55, K55, N80, L80 | Varies by grade | 379-965 | 379-552 | Casing and tubing for oil wells |

| DIN 17175 | St35.8, St45.8 | C: 0.17-0.21, Mn: 0.40-0.80 | 360-460 | 235 min | Boilers, heat exchangers, power plants |

| EN 10216-1 | P235TR1, P265TR2 | C: 0.22 max, Mn: 1.20 max | 360-460 | 235-265 | Pressure vessel piping |

| EN 10216-2 | P235GH, P265GH | C: 0.20-0.25, Mn: 1.10-1.50 | 360-510 | 235-275 | High-temperature service |

| JIS G3454 | STPG370, STPG410 | C: 0.25 max, Mn: 0.30-0.90 | 370-460 | 215-235 | Moderate-pressure pipelines |

| JIS G3455 | STS370, STS410 | C: 0.35 max, Mn: 0.30-1.10 | 370-510 | 235-275 | High-pressure transmission |

| JIS G3456 | STPT370, STPT410 | C: 0.35 max, Mn: 0.30-1.10 | 370-510 | 235-275 | High-temperature pipelines |

Key Notes:

- C = Carbon, Mn = Manganese (other trace elements like Si, S, P may vary).

- Tensile Strength (MPa): Maximum stress before failure.

- Yield Strength (MPa): Stress at which material deforms permanently.

- Grades differ by composition and application (e.g., ASTM A106 Gr. C has higher strength than Gr. A).

Key Benefits of Our Carbon Steel Products

- High Strength and Durability: Ideal for heavy-duty applications.

- Corrosion Resistance: Special coatings enhance longevity.

- Versatility: Suitable for fluid transfer, structural support, and industrial frameworks.

- Customization: Tailored dimensions, thicknesses, and finishes are available.

- Competitive Pricing: Ensuring cost-effective solutions without compromising quality.

Quality Assurance & Certifications

At Vikalp Steel Industries, we prioritize quality and adhere to stringent quality control standards. Our products undergo thorough inspection and testing to ensure:

- Dimensional Accuracy

- Material Integrity

- Corrosion Resistance

- Pressure and Leak Testing

We are certified to meet international quality standards, reinforcing our commitment to delivering superior carbon steel solutions.

Why Choose Vikalp Steel Industries?

- Extensive Product Range: Diverse options to meet various industry needs.

- Industry Expertise: Years of experience in supplying carbon steel pipes and tubes.

- Fast & Reliable Delivery: Ensuring timely supply for urgent requirements.

- Customer-Centric Approach: Dedicated support to ensure customer satisfaction.

- Global Reach: Serving clients worldwide with top-notch products and services.

For premium-quality carbon steel pipes and tubes, trust Vikalp Steel Industries as your reliable partner in steel solutions. Contact us today to discuss your requirements and explore our product range.

Industries We Serve

Our carbon steel pipe and tube solutions are designed to meet the demands of multiple industries, including:

- Oil & Gas Industry: Reliable for pipeline transportation and offshore projects.

- Petrochemical & Chemical Processing: Ensuring corrosion resistance and pressure control.

- Power Plants: Delivering stability in high-temperature environments.

- Marine & Shipbuilding: Supporting marine infrastructure with durable carbon steel.

- Construction & Structural Engineering: Providing strength and stability for building frameworks.

- Automotive & Aerospace: Offering lightweight yet strong materials for industrial applications.

Contact us

Get in Touch with VIKALP STEEL –

Your Trusted Partner for Premium Steel Components! Contact Us Now for a Quote or Consultation.